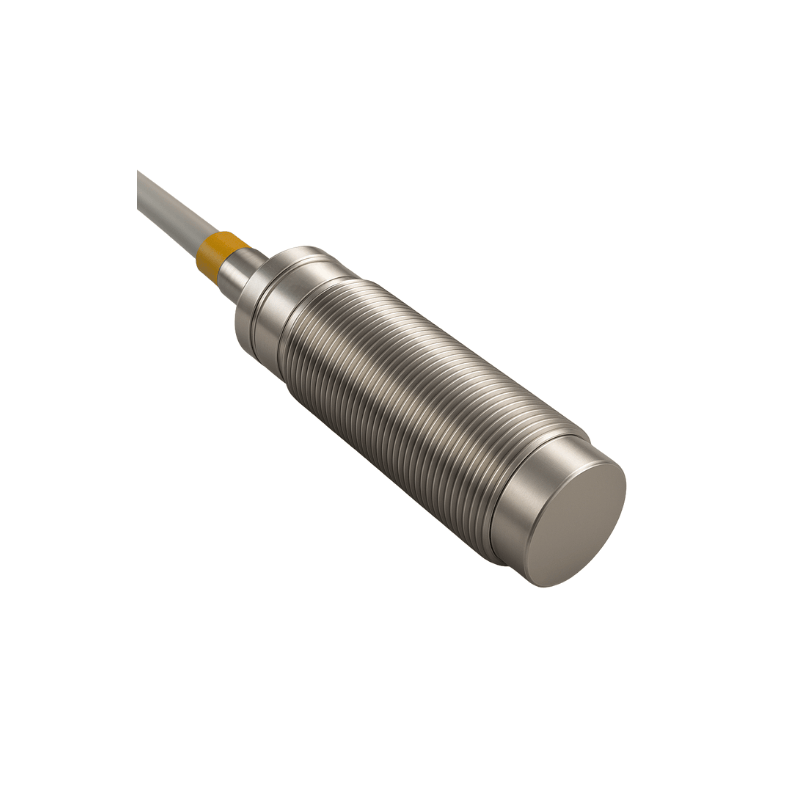

Eddy Current Displacement Sensors for Precision Measurement

The Eddy Current Displacement Sensor is a high-precision, non-contact measurement device designed to accurately measure displacement, position, vibration, and proximity of conductive targets. It is especially suited for industrial and test environments where high speed, high temperature, oil, dust, or vibration make contact-based sensors unreliable or impractical.

Eddy current displacement sensors are widely used in rotating machinery monitoring, shaft position measurement, and dynamic displacement analysis, where stable and continuous measurement is required without mechanical wear. Because the sensing principle is contactless, the sensor maintains long-term accuracy even under continuous operation and harsh environmental conditions.

Measurement Principle

The sensor operates using the principle of electromagnetic induction. A high-frequency alternating current generates an electromagnetic field at the probe tip. When a conductive target enters this field, eddy currents are induced on the target surface. These eddy currents create an opposing magnetic field that alters the impedance of the sensor coil.

The change in impedance is directly related to the distance between the probe and the target. This variation is converted into a precise analog voltage signal proportional to displacement. Because the measurement relies solely on electromagnetic interaction, there is no physical contact, eliminating friction, wear, and mechanical influence on the measurement.

Key Characteristics

Eddy current displacement sensors provide high resolution and fast frequency response, allowing them to capture both static displacement and dynamic vibration. They offer excellent linearity over the calibrated measurement range and maintain stable sensitivity across varying operating conditions.

The rugged probe construction allows reliable operation in environments exposed to oil mist, metal particles, humidity, and elevated temperatures. Their ability to measure very small changes in distance makes them ideal for detecting shaft movement, runout, misalignment, and vibration amplitude in real time.

Because the sensor output is continuous and stable, it is suitable for both monitoring and protection systems, as well as detailed diagnostic and analysis applications.

Typical Applications

Eddy current displacement sensors are commonly used in:

Shaft displacement and vibration monitoring in turbines, compressors, and motors

Rotor dynamics and orbit analysis, including shaft centerline measurement

Bearing clearance and axial position measurement

High-speed rotating machinery diagnostics

Industrial test benches and machinery validation systems

In these applications, accurate non-contact displacement data is critical for early fault detection and system reliability.

System Integration

Eddy current displacement sensors integrate seamlessly with Dynatronic data acquisition systems, vibration monitoring platforms, and machinery protection systems. When combined with velocity sensors, accelerometers, pressure sensors, or temperature sensors, they enable comprehensive condition monitoring and multi-parameter analysis of machine behavior.

Reliable Non-Contact Displacement Measurement

By combining high-resolution sensing, fast response, and robust non-contact design, eddy current displacement sensors provide dependable performance in demanding industrial environments. They are an essential tool for engineers who require precise, continuous displacement measurement to support machinery monitoring, diagnostics, and long-term asset protection.

| Type Number | DTSE102Y | DTSE103Y | DTSE104Y | DTSE105Y | DTSE106Y |

|---|---|---|---|---|---|

| Sensitivity | -8V/mm | -4V/mm | -2.67V/mm | -2V/mm | -1.6V/mm |

| Range | 2mm | 4mm | 6mm | 8mm | 10mm |

| Total length of Sensor | 85mm | 85mm | 85mm | 85mm | 85mm |

| Thread Length | 65mm | 65mm | 65mm | 65mm | 65mm |

| Probe Diameter | Φ14.2mm | Φ14.2mm | Φ20mm | Φ20mm | Φ20mm |

| Power Supply Voltage | -24V | -24V | -24V | -24V | -24V |

| Install Thread | M16X1.5 | M16X1.5 | M16X1.5 | M16X1.5 | M16X1.5 |