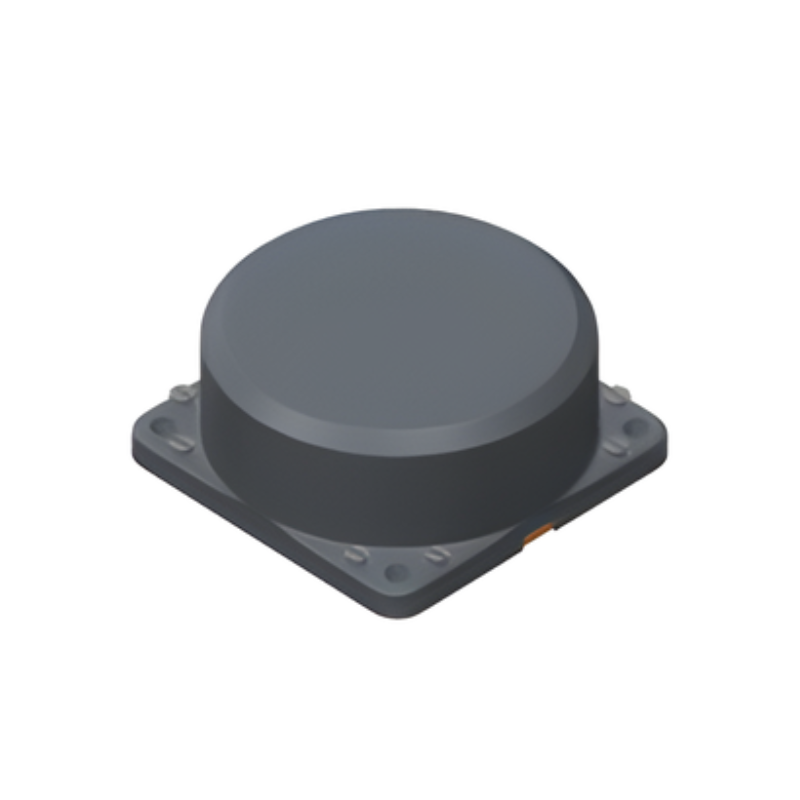

Digital Closed Loop Single Axis Fiber Optic Gyroscope

The Closed-Loop Fiber Optic Gyroscope (FOG) is a high-precision angular rate sensor designed to deliver accurate and stable rotation and orientation measurements in demanding industrial, aerospace, and research applications. Unlike mechanical gyroscopes, fiber optic gyroscopes have no moving parts, resulting in exceptional reliability, long service life, and strong resistance to vibration and mechanical shock.

Closed-loop FOG technology is widely recognized for its ability to provide superior accuracy and stability compared to open-loop designs, making it suitable for applications where precise angular measurement and low drift are critical.

Operating Principle

A fiber optic gyroscope operates based on the Sagnac effect, where light traveling in opposite directions through a coil of optical fiber experiences a phase shift when the system rotates. This phase difference is directly proportional to the angular rate of rotation.

In a closed-loop configuration, the gyroscope actively compensates for the detected phase shift by applying a feedback signal that nulls the error. The amount of feedback required to maintain balance is then used to calculate the angular rate. This closed-loop control significantly improves linearity, dynamic range, and long-term stability, while minimizing bias drift and scale factor errors.

Because the sensing mechanism relies purely on optical signals, the gyroscope is immune to electromagnetic interference and does not suffer from wear or friction.

Key Characteristics

Closed-loop fiber optic gyroscopes offer excellent accuracy, low noise, and outstanding repeatability over extended operating periods. They provide fast response and high resolution, enabling precise detection of both slow rotational motion and rapid dynamic changes.

Their solid-state design ensures stable operation under harsh environmental conditions, including vibration, temperature variation, and continuous operation. Compact form factors and low power consumption make them suitable for both embedded systems and standalone measurement setups.

Typical Applications

Closed-loop fiber optic gyroscopes are widely used in applications requiring reliable and precise angular measurement, including:

Inertial Navigation Systems (INS): Providing angular rate input for navigation and orientation

Aerospace & UAV Testing: Flight control validation, attitude measurement, and stability analysis

Industrial Motion Monitoring: Tracking rotational behavior of platforms and machinery

Marine & Offshore Systems: Navigation and stabilization in challenging environments

Research & Education: Experimental studies involving rotational dynamics and inertial sensing

In many of these applications, the long-term stability and low drift of closed-loop FOGs are critical to maintaining accuracy without frequent recalibration.

Integration with Measurement Systems

The closed-loop fiber optic gyroscope is designed for seamless integration with Dynatronic data acquisition and inertial measurement systems. When combined with accelerometers, AHRS units, or navigation processors, the gyroscope forms a core component of advanced motion and orientation measurement solutions. Synchronizing angular rate data with parameters such as vibration, temperature, or displacement enables comprehensive system analysis and validation.

Precision Rotation Measurement Without Mechanical Limitations

By combining optical sensing, closed-loop control, and robust solid-state construction, closed-loop fiber optic gyroscopes deliver highly reliable angular measurement without the limitations of mechanical systems. They are an ideal solution for engineers who require accurate, stable, and maintenance-free rotation sensing in mission-critical and long-duration applications.

| Type Number | DT-AgileLight-320A |

|---|---|

| Measurement Range | ±530°/s |

| Bias Stability | ≤0.1°/h (1σ, 10s) |

| Resolution | 0.06°/h |

| Relative Error of Scale Factor | ≤100 ppm |

| 3 dB Dynamic Response Frequency Band | ≥1 kHz |

| Withstand Maximum Vibration | 18 g |

| Withstand the Maximum Impact | 100 g, 6 ms, half sine wave |

| Operating Temperature | -45°C ~ +70°C |

| Storage Temperature | -55°C ~ +85°C |

| Volume | ≤59.6 mm × 59.6 mm × 26.3 mm |

| Weight | ≤150 g |

| Installation Dimensions | 4–φ4.2 mm |

| Power Consumption | ≤4 W |

| Supply Voltage | +5 VDC |

| Electrical Interface | RS422 |