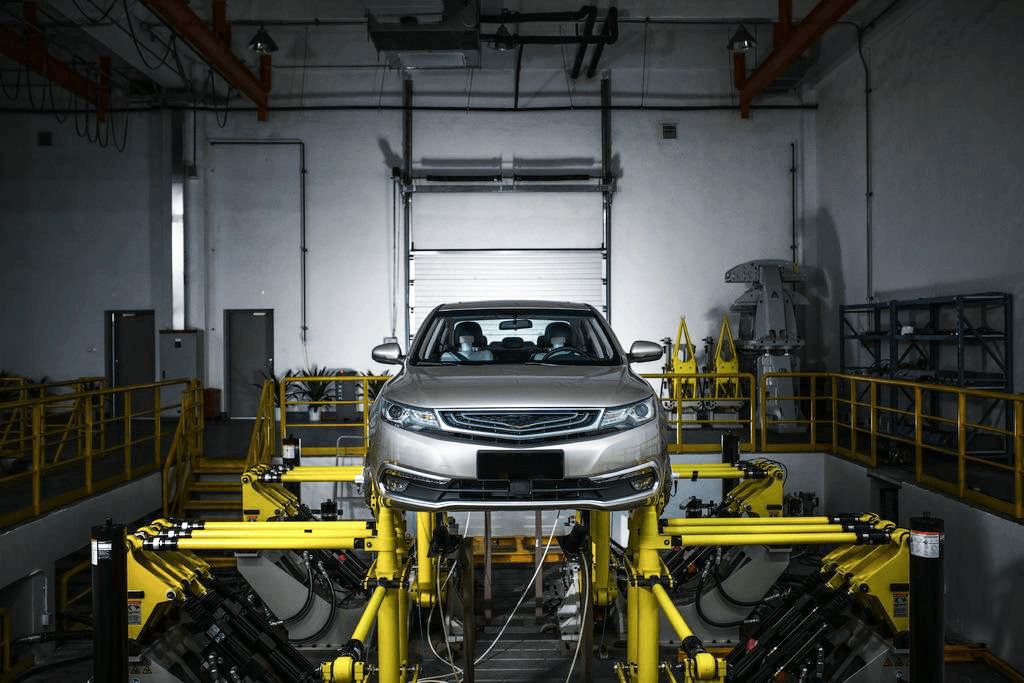

The stress of each point of the mechanical part changes periodically with time during the work. This kind of stress is called alternating stress (cyclic stress). Under the action of alternating stress, the stress on the part is lower than the yield point of the material, but after a long period of work, the part will crack or suddenly break completely. This phenomenon is called fatigue. Therefore, the fatigue durability test is to study the fatigue failure of car body or parts under the repeated variable load.

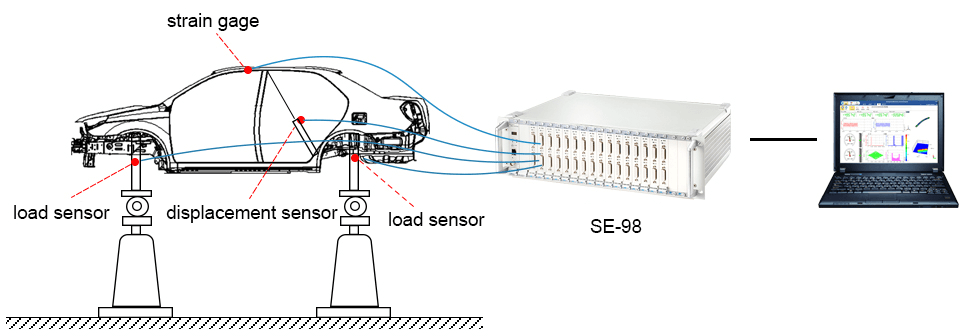

SE-98 Dynamic Stress-strain Testing and Analysis System is specially designed for structural strength and fatigue life assessment tests. It adopts a 19-inch standard chassis structure and uses Gigabit Ethernet switches to expand. A single computer is able to collect data and control tens of thousands of channels.

During the long-term use, each car component is inevitably always in a state of cyclic stress, which can cause fatigue problems. As a result, fatigue durability tests on the car body or parts are the key to ensure the stable working of automobile for a long time. The Dynatronic solution is fast, suitable and professional. By using SE-98 to collect data, the experts can perform the extensive analysis and create statistics.