Measurement Piezoelectric Ceramic Vibration Characteristics

1. Project Background & Challenges

Piezoelectric ceramics are key smart materials that convert electrical energy into mechanical energy (inverse piezoelectric effect), widely used in:

Precision Positioning: Scanning probe microscopes, optical platform stabilization.

Ultrasonic Equipment: Ultrasonic imaging probes, ultrasonic welding, cleaning.

Vibration Control: Active vibration damping systems.

Acoustic Devices: Micro speakers, microphones.

The main challenges in characterizing their performance include:

Micro/Nano-scale Displacement: Vibration amplitudes are typically in the nanometer to micrometer range, difficult to capture accurately with traditional methods.

High-Frequency Response: Operating frequencies can range from Hz to MHz, requiring very high measurement bandwidth.

No Added Mass: The mass of contact sensors (e.g., accelerometers) severely alters the piezoelectric ceramic's own resonant frequency and response, leading to distorted measurements.

Need for Complete Amplitude and Phase Information: Essential for analyzing system dynamic behavior.

2. Solution: Non-Contact Laser Vibrometry System

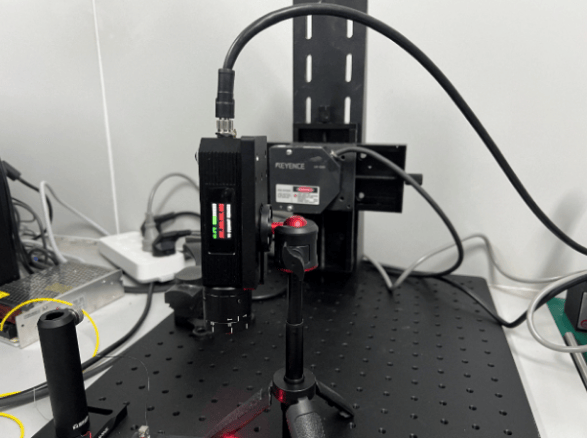

This solution utilizes the high precision and non-contact characteristic of the Dynatronic VibroMicro VM-S-100 to directly measure the vibration of the piezoelectric ceramic surface.

System Configuration:

Core Sensing Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer.

Drive System:

Signal Generator: Produces pure sine waves, sweep signals, or square waves.

Power Amplifier: Amplifies the signal generator voltage to levels sufficient to drive the piezoelectric ceramic (typically tens to hundreds of volts).

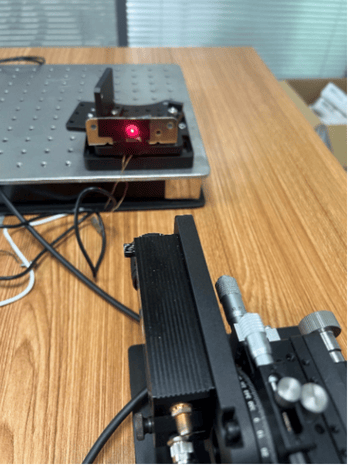

Device Under Test (DUT): Piezoelectric ceramic chip or actuator, properly fixed (e.g., free boundary or clamped boundary).

Data Acquisition & Analysis: VibroSoft or other professional spectrum analysis software.

3. Test Method & Procedure

System Setup:

Securely fix the piezoelectric ceramic on an optical table or vibration isolation platform.

Precisely focus the laser vibrometer spot on the point to be measured (usually the center point or the antinode of a specific mode).

Ensure the laser beam is perpendicular to the measurement surface to obtain the best signal-to-noise ratio.

Connect: Signal Generator -> Power Amplifier -> Piezoelectric Ceramic.

Test Content & Steps:

a) Frequency Response Function (FRF) Measurement

Setup: The signal generator outputs a constant voltage sweep signal (e.g., 100 Hz - 1 MHz).

Measurement: The VibroMicro VM-S-100 measures the vibration velocity response of the piezoelectric ceramic.

Output: The system directly generates the Magnitude-Frequency Characteristic Curve and the Phase-Frequency Characteristic Curve.

b) Resonant Frequency & Amplitude Measurement

Identify the resonance peaks from the magnitude-frequency curve; their corresponding frequencies are the resonant frequencies of the piezoelectric ceramic under those boundary conditions.

At the resonant frequency, switch to a single sine wave drive and directly read the displacement amplitude (units: nm, μm) and vibration velocity measured by the VibroMicro VM-S-100.

c) Transient Response Analysis

Setup: The signal generator outputs a square wave or pulse signal.

Measurement: The VibroMicro VM-S-100 captures the step response or free decay vibration of the piezoelectric ceramic.

Analysis: Calculate the damping ratio from the decay vibration; observe the overshoot and settling time of the step response.

4. Typical Results & In-Depth Analysis

4.1 Frequency-Amplitude Relationship

Result: Obtain a clear magnitude-frequency characteristic curve, showing the first-order, second-order, and even higher-order resonance modes of the piezoelectric ceramic.

Value:

Determine Operating Bandwidth: Ensure the piezoelectric ceramic operates in the flat region away from resonance peaks to avoid phase jumps and distortion.

Quality Inspection: Shifts in resonant frequency may indicate material aging, cracking, or bonding layer failure.

4.2 Voltage-Displacement Curve

Result: At a specific frequency (typically a static or quasi-static frequency well below resonance), measure the displacement corresponding to different drive voltages and plot the voltage-displacement curve.

Value:

Calibrate Piezoelectric Constant: The slope of the curve reflects the displacement coefficient of the piezoelectric ceramic (units: nm/V).

Identify Hysteresis: The inherent hysteresis of piezoelectric materials manifests as a loop on the curve; the laser vibrometer can accurately quantify this nonlinear effect.

4.3 Harmonic Distortion Analysis

Result: When driven by a single-frequency sine wave, analyze the spectrum of the vibration signal. Ideally, only the drive frequency (fundamental) should be present, but in practice, second, third harmonics, etc., appear.

Value: The Total Harmonic Distortion (THD) is a key indicator for assessing the linearity and motion purity of piezoelectric ceramics, crucial for high-fidelity audio and precision positioning.

5. Core Advantages of VibroMicro VM-S-100

Unmatched Precision: Displacement resolution down to picometer/nanometer level, easily handling the tiny vibrations of piezoelectric ceramics.

Ultra-Wide Bandwidth: Frequency range from DC to 25MHz, perfectly covering the entire operating spectrum of piezoelectric ceramics.

Absolutely No Mass-Loading: Optical measurement completely avoids affecting the intrinsic dynamics of the piezoelectric ceramic, ensuring true and reliable results.

Simultaneous Amplitude & Phase Acquisition: Provides complete information for a thorough understanding of the dynamic behavior of piezoelectric ceramics.

6. Application Prospects

R&D and Design: Provides reliable validation data for the development of new piezoelectric materials and device design.

Quality Control: Enables rapid, non-destructive performance screening and grading of piezoelectric elements on production lines.

System Integration Verification: Verifies whether piezoelectric actuators integrated into larger systems (e.g., scanning mirrors, active dampers) are functioning correctly.

Conclusion:

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer is the ideal tool for characterizing the vibration properties of piezoelectric ceramics. With its absolute advantages of high precision, wide bandwidth, and non-contact operation, it provides users with a true picture of the "frequency" vs. "amplitude" relationship of piezoelectric ceramics, making it an indispensable key measurement instrument for advancing piezoelectric technology from research to high-quality manufacturing.