Bone Conduction Headphone Acoustic Testing with VibroMicro

1. Technology Background

Bone conduction is a sound transmission method that converts audio signals into mechanical vibrations, transmitting sound waves through the human skull, bony labyrinth, inner ear lymph fluid, spiral organ, and auditory nerve to the hearing center. Compared with air conduction, bone conduction eliminates many sound transmission stages, enabling clear sound reproduction in noisy environments.

With advantages including hearing safety and noise immunity, bone conduction technology has long been used in medical, military, scientific research, and professional sports fields. As technology advances and living standards improve, bone conduction headphones, glasses, helmets and other products are increasingly favored by consumers.

2. Testing Challenges & Traditional Methods

2.1 Traditional Testing Limitations:

Sound pressure transmission through air, collected by microphones

Multiple sound-electricity signal conversions with significant signal loss

Measurement systems typically require artificial ears and analyzers

Indirect measurement cannot accurately reflect actual vibration performance

2.2 Industry Requirements:

Direct vibration source measurement

High-precision vibration parameter acquisition

Frequency response characteristic validation

Production line compatibility

3. Dynatronic Solution Design

3.1 Testing Principle

Coherent laser interferometry for direct vibration source measurement

Complete vibration parameter acquisition: phase, amplitude, velocity, acceleration, frequency

Professional waveform analysis tools

3.2 Test Configuration

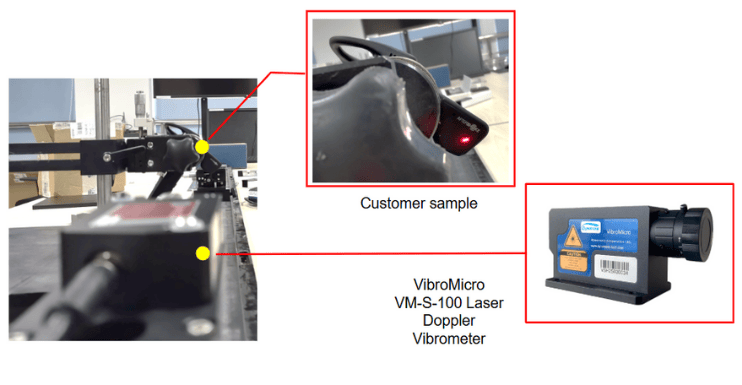

Test Device: Brand X Bluetooth bone conduction headphones

Mounting Method: Headphone fixed via bracket on one side

Audio Source: Huawei Mate 20 smartphone via Bluetooth

Signal Generator: Frequency Sound Generator APP

Volume Range: 0-MAX

Frequency Range: 20-20,000 Hz

Testing Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Analysis Software: Dynatronic VibroSoft

4. Testing Methodology

4.1 Test Setup

Secure headphone transducer unit in fixed position

Align laser beam perpendicular to vibration surface

Establish Bluetooth connection with signal generator app

Configure sweep frequency parameters (20Hz-20kHz)

4.2 Data Acquisition

Execute frequency sweep while recording vibration data

Capture complete vibration waveform characteristics

Analyze frequency response and harmonic distortion

Measure vibration amplitude at different frequency points

5. Results Analysis

5.1 Performance Validation

Bluetooth transmission functionality: Normal operation

Frequency response range: 20-20,000 Hz achieved

Sensor capability: Meets frequency response testing requirements

Vibration frequency measurement: High stability, minimal error

5.2 Key Findings

Mounting method may affect amplitude measurements and cause resonance

Direct vibration measurement provides accurate performance characterization

Non-contact method eliminates loading effects on lightweight transducers

6. Technical Advantages

6.1 Measurement Performance

High Sensitivity: Nanometer-level displacement resolution

Non-contact Operation: No interference with device under test

Direct Signal Acquisition: Optical measurement of vibration source

Comprehensive Parameters: Phase, amplitude, velocity, acceleration, frequency

6.2 Practical Benefits

Compact Size: Minimal space requirements for integration

Flexible Installation: Adaptable working distances

Production Suitability: Ideal for inline measurement systems

High Accuracy: Minimal measurement error for reliable results

7. Implementation Value

7.1 Quality Assurance

Objective evaluation of acoustic performance

Quantitative vibration parameter measurement

Consistent testing standards across production

7.2 Development Support

Rapid prototype validation

Design optimization guidance

Performance benchmarking

7.3 Production Benefits

100% inline testing capability

Reduced manual inspection requirements

Comprehensive data traceability

8. Conclusion

The Dynatronic VibroMicro VM-S-100 based testing solution provides an advanced method for bone conduction headphone acoustic performance evaluation. By directly measuring vibration characteristics through non-contact laser interferometry, it overcomes limitations of traditional acoustic testing methods. The system delivers high-precision, reliable measurements suitable for both R&D validation and production line integration, supporting the growing bone conduction audio device market with robust quality assurance capabilities.