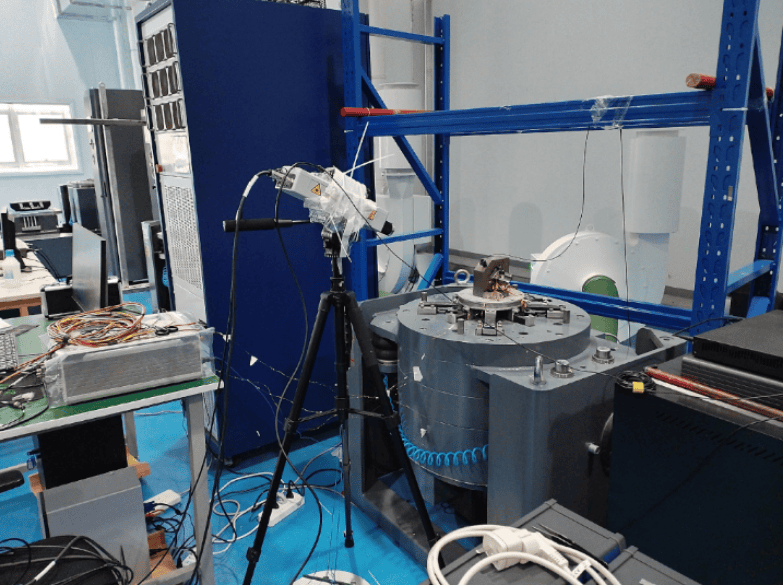

Multi-Channel Laser Vibrometer for Modal Testing

A national aerospace institute used Dynatronic’s VibroMicro VM-S-100 Multi-Channel Laser Doppler Vibrometer to perform modal testing of high-temperature materials. The system delivered precise, non-contact vibration measurements across multiple points, revealing natural frequencies, damping ratios, and mode shapes vital for aerospace material research and design optimization.

ODS Analysis of Aero Thin-Walled Panel Structure

Dynatronic’s VibroMicro Laser Doppler Vibrometers were used to analyze the operational deflection shapes of thin-walled aero panels under high-temperature acoustic excitation. The test visualized vibration modes, identified fatigue-prone areas, and provided crucial data for improving structural design and ensuring reliability in extreme environments.

Innovative Use of VibroMicro in Aero-Engine Testing

A national aerospace institute employed Dynatronic’s VibroMicro Laser Doppler Vibrometer and DE-944 data system to measure aero-engine blade vibrations at 800°C. This high-temperature, non-contact testing validated VibroMicro’s precision, stability, and cost-effectiveness—establishing it as the chosen solution for advanced aero-engine research.

Laser Doppler Vibrometers Applications in Aircraft Research

Laser Doppler Vibrometers (LDVs) have become essential in modern aircraft research. With non-contact precision and full-field vibration mapping, they enable aeroelastic testing, modal analysis, and structural diagnostics—advancing aircraft safety, performance, and noise control from component development to full-scale flight validation.