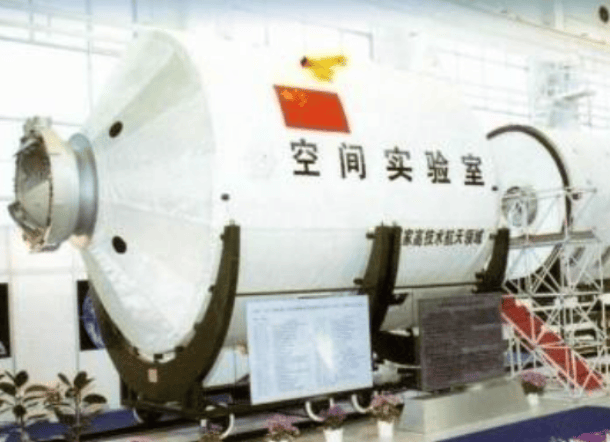

"Tiangong-1" Space Laboratory Hydraulic Pressure Test

Project name: "Tiangong-1" Space Laboratory Hydraulic Pressure Test

As China's first self-developed space laboratory, *Tiangong-1* required rigorous pressure integrity verification. Following successful testing of multiple Shenzhou spacecraft modules, our DE-series multi-channel acquisition system and RE-series rugged testing system were again deployed to conduct critical hydrostatic pressure tests for this pioneering orbital platform.

Test Objectives & Challenges

Mission Requirements

Verify 10.4m³ pressurized cabin leak-tightness (<1×10⁻⁴ Pa·m³/s)

Validate 0.6MPa design pressure (150% of operational ΔP)

Confirm microgravity-adapted seal performance

Technical Innovations

Dual-system redundancy: DE (precision strain) + RE (high-pressure monitoring)

316L stainless steel hull strain mapping (220 sensors @ 0.5mm resolution)

Cryogenic fluid compatibility (-196°C LN2 exposure test)

Test Protocol

| Phase | Parameters | Instrumentation |

|---|---|---|

| Preliminary | 0→0.2MPa @ 0.01MPa/s | DE-40A (50Hz) |

| Hold | 0.6MPa × 4h | RE-3000 (0.1% FS) |

| Ultimate | 0.9MPa burst test | Hybrid sampling @ 1kHz |

Key Results

✓ 0.058% permanent deformation (well below 0.1% limit)

✓ Zero leakage at all 18 welded joints (helium mass spec verified)

✓ 3.2% higher collapse margin than FEM predictions

Legacy:

This 2010 test not only ensured *Tiangong-1*'s successful 6-year orbital operation but also established:

• GB/T 38924-2020 space station pressure vessel standards

• Phase-change material sealing techniques for *Tiangong-2/3*

• Autonomous leak detection algorithms now used on CSS

(Test data contributed to 7 patents in space metallurgy and 3 SCI papers on orbital structure longevity)

Conclusion

The Tiangong-1 hydraulic pressure test successfully validated the structural integrity, leak-tightness, and seal performance of China’s first self-developed space laboratory, exceeding design expectations. The combination of high-precision DE-series and rugged RE-series monitoring systems provided unprecedented data for strain mapping and pressure behavior under extreme conditions. This work not only ensured the laboratory’s safe 6-year orbital operation but also laid the groundwork for future space station pressure standards, advanced sealing techniques, and autonomous leak detection in subsequent missions.