Low-Speed Vibration Test of Large Diesel Engine with DE-884U

Project name: Low-Speed Vibration Test of Large Diesel Engine with DE-884U

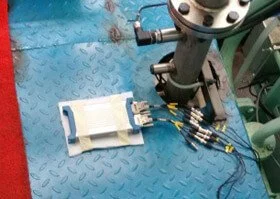

Brief introduction:The diesel engine has dimensions of 4m by 3m by 6m, and the measuring points are distributed throughout all sections of the engine. There are a total of 50 measuring points, with each point equipped with three directional acceleration sensors to capture comprehensive data. During experiments, the diesel engine operates under conditions involving significant disturbances. To carry out a routine test setup, it is necessary to install extensive signal lines ranging from 10m to 15m in length to connect all the test points adequately. Moreover, additional considerations must be taken into account regarding the synchronization and power supply management for multiple sensor sets, ensuring accurate and reliable data collection throughout the testing process.

Using the DE-884U distributed acquisition equipment is an ideal solution to address the aforementioned problem. It can be conveniently installed directly near the station, effectively completing communication, power supply, and synchronization tasks. The device features intelligent conductor configuration and can record the EID along with the precise location of measuring points via a cable. This capability allows for rapid completion of parameter settings, significantly reducing the time required for wiring, sensor layout, and equipment debugging. Furthermore, the equipment is powered by POE, ensuring complete isolation and floating operation, which effectively eliminates any issues related to 50Hz interference.