Mobile Motor Start-Stop Dynamics Quality Testing Using VM-S-100

The haptic feedback from a mobile phone motor is a critical aspect of the user experience, defining the phone's sense of refinement. High-quality motor vibration is characterized by crisp, clean, and powerful start-stop transitions.

Dynatronic's testing solution enables the quantitative analysis of these dynamic motor characteristics.

Customer Need: Enhance the quality of mobile phone haptic feedback and establish precise, objective performance evaluation and quality control for motors.

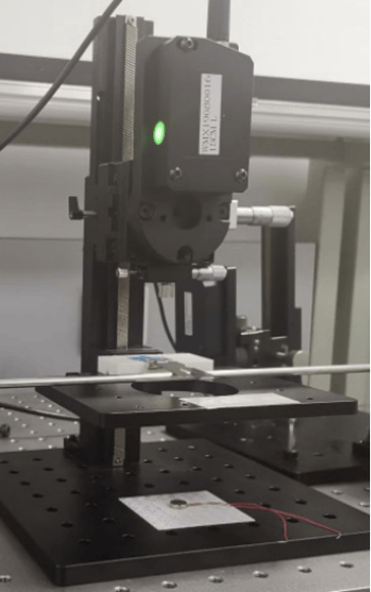

Testing Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Application Objective: Quantitative analysis of the start-stop dynamics of Linear Resonant Actuators (LRAs) and Eccentric Rotating Mass (ERM) motors.

1. Background and Testing Purpose

The motor is the core component providing haptic feedback in smartphones. Its vibration quality directly impacts the user's tactile experience. An optimal motor vibration should feel "crisp and clean" and "powerful," which specifically translates to:

Rapid Start-Up: Instantly reaching the target amplitude upon power-on.

Precise Braking: Stopping immediately after power-off with no residual oscillation.

Pure Waveform: The vibration waveform should highly match the drive signal, free of distortion or noise.

Traditional evaluation methods, such as manual auditory assessment or contact sensors, are subjective, prone to interference, and offer limited accuracy. This project utilizes the Dynatronic VM-S-100 Laser Vibrometer to establish a non-contact, high-precision, and quantifiable testing solution for motor start-stop dynamics. This provides objective data support for motor R&D, production quality inspection, and fault analysis.

2. Testing System and Advantages

Core Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

System Advantages:

Non-Contact Measurement: Completely avoids mass-loading effects on the miniature motor (often weighing only a few grams), capturing its most authentic vibration state.

Ultra-High Precision and Resolution: Provides nanometer-level displacement resolution and extremely high temporal resolution, accurately capturing subtle dynamic changes at the moment of motor start and stop.

Wide Frequency Response: Easily covers the operating bandwidth of phone motors from tens of Hz to several kHz, ensuring waveform integrity without distortion.

Intuitive and Efficient: Measurement requires only a laser spot, eliminating the need for fixtures, simplifying setup, and significantly improving testing throughput.

3. Test Setup and Procedure

Measurement Point Setup: The laser vibrometer's beam is focused precisely on the most representative vibrating part of the phone motor's mass block or casing.

Signal Synchronization: The motor's drive signal is synchronized with the laser vibrometer's data acquisition system.

Data Acquisition: When a short pulse or specific waveform drive signal is applied to the motor, the vibration velocity or displacement time-domain signal is captured synchronously.

4. Data Analysis Methodology

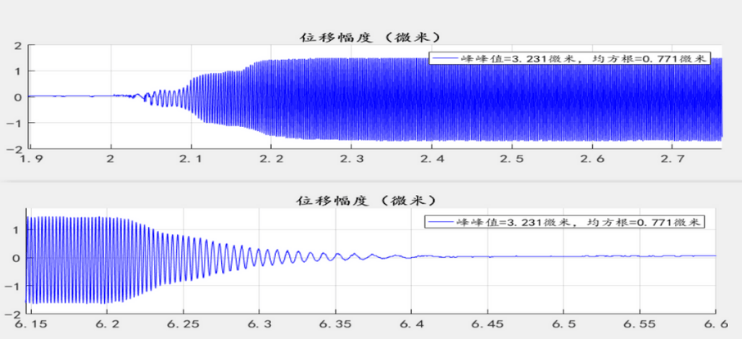

By analyzing the captured high-fidelity time-domain waveform, several key quantitative parameters can be extracted to evaluate the motor's start-stop characteristics:

Start-Up Response Time: The time required from the beginning of the drive signal until the vibration reaches a specified percentage (e.g., 90%) of the target amplitude. A shorter time indicates a "crisper" start.

Braking Stop Time: The time required from the end of the drive signal until the vibration decays to near zero (e.g., falls below 10% of the amplitude). A shorter time indicates a "cleaner" stop.

Overshoot & Undershoot: Analysis of whether the vibration exceeds the target amplitude (overshoot) or fails to reach it (undershoot) during the start-up phase.

Residual Oscillation: Analysis of any unnecessary, often chaotic, ringing after the braking phase. An ideal motor should have virtually no residual oscillation.

Waveform Fidelity: Comparison between the measured vibration waveform and the ideal drive waveform to calculate the level of distortion.

5. Results and Conclusion

Testing with the VM-S-100 transforms subjective perceptions like "crisp and clean" or "powerful" into objective, comparable engineering data.

Exemplary Test Results:

High-Quality Motor: The test waveform shows very short start-up and braking stop times (e.g., both within a few milliseconds). The waveform has steep rising and falling edges, and the curve after braking is smooth and clean, with no residual oscillation.

Low-Quality Motor: The test waveform reveals a slow start-up, noticeable ringing or "tail" after braking, and a distorted waveform.

Conclusion:

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer provides a revolutionary solution for quality control of haptic feedback in mobile phone motors. It enables the quantitative measurement of start-stop dynamics with millisecond timing and nanometer precision, making the motor "feel" visible and quantifiable. This not only assists R&D engineers in optimizing motor design and drive algorithms but also provides an efficient and reliable standard for 100% quality inspection on production lines. Ultimately, it empowers smartphone manufacturers to enhance the overall user experience and market competitiveness of their products.