Quality Testing of Film Speakers Using VibroMicro VM-S-100

1. Background and Testing Challenges

With the widespread adoption of high-fidelity waterproof film speakers in smartphones and automotive electronics, ensuring their acoustic quality has become crucial. Film speakers present unique testing challenges due to their specific characteristics:

Key Challenges:

Small Area, High Energy: Compact speaker films generate significant vibration energy in a small area

Harmonic Generation: Prone to producing unwanted harmonics that degrade sound quality

Complex Vibration Patterns: Intricate vibration modes affect acoustic performance

Quality Control: Traditional methods struggle to quantify subtle acoustic defects

Waterproof Design: Conventional contact measurement methods are often unsuitable

2. Testing Solution

2.1 System Configuration

Core Sensor: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Excitation System: Audio power amplifier with programmable signal generator

Analysis Platform: VibroSoft with specialized acoustic analysis modules

Fixture System: Acoustic-isolated test chamber

2.2 Measurement Capabilities

Full-field Vibration Mapping: Non-contact scanning of entire speaker surface

Harmonic Analysis: Precise detection of harmonic distortion components

Modal Analysis: Complete characterization of vibration mode shapes

Real-time Monitoring: Continuous quality assessment during production

3. Testing Methodology

3.1 Test Setup

Speaker Mounting: Secure film speaker in acoustic test fixture

Laser Positioning: Align laser perpendicular to speaker surface

Signal Configuration: Program sweep signals (20Hz-20kHz) and specific frequency tones

Data Acquisition: Capture vibration responses at multiple surface points

3.2 Test Procedure

Frequency Response Testing:

Apply logarithmic sweep signals

Measure vibration velocity across frequency spectrum

Identify resonance frequencies and anti-resonance points

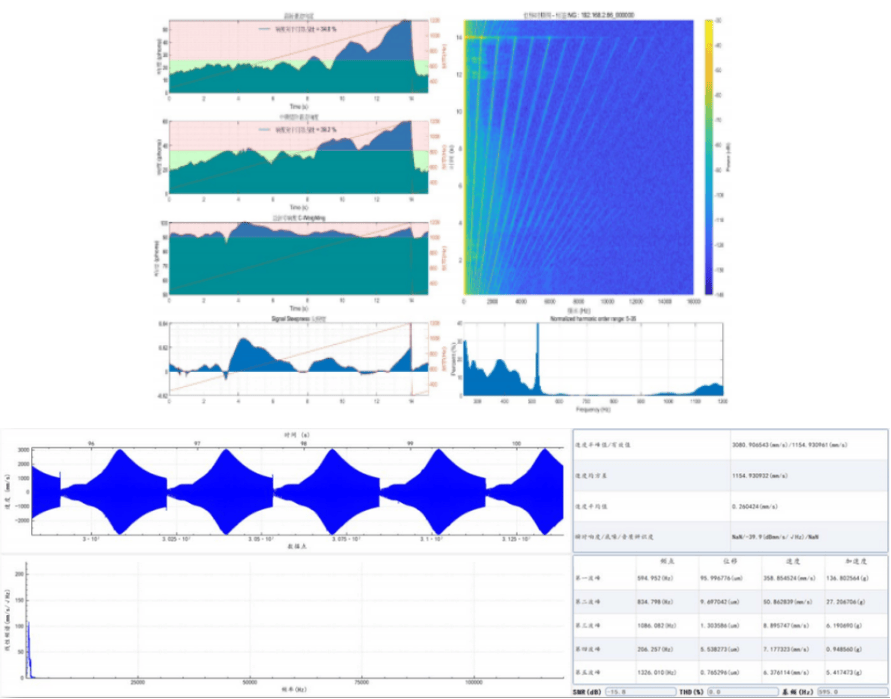

Harmonic Distortion Analysis:

Drive with pure tone signals at reference frequencies

Detect and quantify harmonic components (2nd, 3rd, etc.)

Calculate Total Harmonic Distortion (THD)

Modal Analysis:

Scan multiple points across speaker surface

Reconstruct complete vibration mode shapes

Identify unwanted vibration patterns and standing waves

4. Technical Implementation

4.1 Signal Processing Approach

Measurement Process:

Pure Tone Excitation

→ Laser Vibration Acquisition

→ FFT Spectrum Analysis

→ Harmonic Component Extraction

→ THD Calculation

→ Mode Shape Reconstruction

4.2 Key Analysis Parameters

Fundamental Frequency Range: 20 Hz - 20 kHz

Harmonic Detection: Up to 5th order harmonics

Vibration Amplitude Range: 0.1 μm - 100 μm

THD Measurement Accuracy: ±0.5%

4.3 Quality Assessment Criteria

Frequency Response: Flatness within ±3 dB

Harmonic Distortion: THD < 1% @ reference output

Mode Shape Purity: Clean, expected vibration patterns

Resonance Control: Controlled resonance distribution

5. Test Results and Analysis

5.1 Performance Metrics

Measurement Resolution: 0.01 μm displacement accuracy

Frequency Resolution: 0.1 Hz in audio range

Spatial Resolution: 10 μm laser spot size

Testing Efficiency: < 15 seconds per complete analysis

5.2 Typical Quality Indicators

High-Quality Speaker:

Smooth frequency response curve

Low harmonic distortion across operating range

Clean, symmetrical vibration modes

Controlled resonance behavior

Defective Speaker Patterns:

Abnormal harmonic peaks

Irregular vibration mode shapes

Unwanted resonance frequencies

Nonlinear response characteristics

6. System Advantages

6.1 Measurement Performance

High Sensitivity: Capable of detecting sub-micron vibrations

Wide Dynamic Range: Suitable for both small and large vibration amplitudes

Excellent Linearity: Accurate measurement across entire operating range

Phase Coherence: Preserves phase information for modal analysis

6.2 Production Suitability

Non-contact Operation: No loading effect on delicate film structures

Rapid Testing: Compatible with production line cycle times

Environmental Immunity: Unaffected by acoustic field or air movements

Automation Ready: Easy integration with robotic positioning systems

6.3 Analytical Capabilities

Comprehensive Analysis: Combined time-domain and frequency-domain analysis

Visualization Tools: Intuitive display of vibration modes and harmonic content

Quantitative Metrics: Objective quality parameters for consistent judgment

Statistical Analysis: Process control capabilities for mass production

7. Application Value

7.1 Quality Assurance

Objective Quality Grading: Quantitative replacement for subjective listening tests

Early Defect Detection: Identification of manufacturing variations

Performance Validation: Verification of design specifications

Batch Consistency: Ensuring uniform quality across production lots

7.2 Product Development

Design Optimization: Data-driven improvement of speaker geometry and materials

Failure Analysis: Identification of root causes for acoustic defects

Competitive Benchmarking: Objective comparison with reference designs

Innovation Support: Enabling development of next-generation speaker technologies

7.3 Cost Reduction

Reduced Rework: Early detection of manufacturing issues

Lower Return Rates: Improved field reliability through better screening

Efficient Production: Faster testing compared to acoustic chamber methods

Labor Savings: Automation reduces manual testing requirements

8. Implementation Case

Application Scenario: Smartphone film speaker production line

Testing Volume: 500 units per hour

Measurement Points: 25-point grid scan per speaker

Quality Improvement: 60% reduction in acoustic-related returns

Process Impact: Enabled implementation of statistical process control for acoustic parameters

Conclusion:

The Dynatronic VibroMicro VM-S-100 based testing system provides an advanced solution for quality assessment of film speakers in mobile and automotive applications. By offering precise measurement of vibration characteristics and harmonic distortion, it enables manufacturers to implement quantitative quality standards and drive continuous improvement in acoustic performance. The non-contact approach combined with comprehensive analytical capabilities makes it an invaluable tool for both product development and high-volume manufacturing quality control.