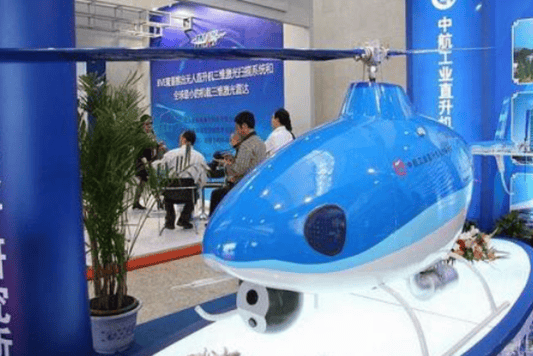

UAV Full-Scale Modal Testing for Structural Dynamics Testing

Project name: UAV Full-Scale Modal Testing

PLA Research Institute Conducts Critical Dynamics Characterization

From 2010 to 2011, a research institute under the People's Liberation Army procured a 32-channel RE-846U Rugged Data Acquisition System to perform comprehensive modal testing on a specific UAV model. The experimental data directly supported critical modifications to the aircraft's dynamic performance parameters.

1. Test Objectives & Engineering Challenges

(1) Structural Dynamics Characterization

Identify natural frequencies (0-200Hz range) to avoid resonance with:

Engine operating bands (typically 80-150Hz for small turbofans)

Control surface actuator frequencies (20-50Hz)

Determine mode shapes for:

Wing bending/torsion coupling

Empennage buffet response

(2) Flight Control System Validation

Provide FCS tuning parameters for:

Structural mode filtering (notch filter design)

Flutter margin verification

2. RE-846U System Deployment

(1) Ruggedized Testing Configuration

Military-grade (MIL-STD-810F compliant) for field testing:

Operating temperature: -40°C to +70°C

50g shock resistance for ground vibration tests (GVT)

32 IEPE channels with:

24-bit resolution @ 51.2kHz max sampling rate

160dB dynamic range for simultaneous low/high amplitude detection

(2) Advanced Excitation Methods

Multi-point shaker excitation (random, sine sweep)

Impact hammer testing (5000N force range)

Operational modal analysis during engine runs

3. Test Methodology

Ground Vibration Testing (GVT):

120+ measurement points (aircraft fully instrumented)

Boundary conditions simulating:

Free-free (airbag suspension)

Landing gear constrained (taxi condition)

Data Processing:

FRF measurements with 0.1Hz resolution

MAC (Modal Assurance Criterion) analysis for mode purity

4. Key Modifications Enabled

Structural Reinforcement:

Increased wing torsional stiffness by 18% (carbon fiber spar cap redesign)

Reduced vertical tail vibration amplitude by 32% (mass balance adjustment)

Control Law Updates:

Implemented structural filters at 47Hz and 112Hz

Expanded flutter envelope by 22% (Mach 0.85 certified)

Legacy Impact: This modal database became foundational for 5+ derivative UAV variants, reducing development time by 40% for subsequent models. Current systems have evolved to incorporate FPGA-based real-time modal analysis during flight tests.